WHY CUSTOMIZED GLASS BOTTLE?

SGSBOTTLE is a leading custom glass bottle manufacturer offering tailored design, mold development, and packaging solutions for food, beverage, and cosmetic brands worldwide.

If you want your brand to stand out, custom glass bottles are the perfect solution. Whether it’s a distinctive shape, unique color, specialized closure, or eye-catching decoration, customization allows your packaging to reflect your product’s identity.

At SGSBOTTLE, our experienced in-house design team is committed to bringing your vision to life—tailoring glass bottles, jars, and containers to meet your exact specifications.

Expertise You Can Trust with Your Craft

Having an experienced and trustworthy partner will ensure that you get to market on time and on budget. SGSBOTTLE has served the distiller, wine, and craft beverage community for more than 20 years, combining our expertise and commitment to your success with modern packaging technologies.

Full Turnkey Solution Makes It Easy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Full Turnkey Solution Makes It Easy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Full Turnkey Solution Makes It Easy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Full Turnkey Solution Makes It Easy

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Wide Custom Options for Your Unique Glass Packaging

Your products are carefully engineered and crafted for your unique packaging experience. With the help of our dedicated specialists and craftsmen, we offer a myriad of customization options, including choosing from Pantone color, selecting shapes and closures, capacity, and surface treatment.

Capacity

Determined by desired price point and usage occasion etc

Color

Matching your brand to the right color and quality glass

Shape

Driven by consumer desire for options, from the traditional to exotic

Decoration

Unique options create a distinctive shelf presence

Finish

Essential to protecting the long-term integrity of the bottle

Surface

Unique options create a distinctive shelf presence

Mold Cost & Lead Time

SGSBOTTLE provides highly competitive pricing, MOQs, and turnaround times. This is thanks to Chinese cost-efficiency throughout the entire production cycle of your glass bottles.

Degisn & 3D Samples

USD $300

1 weeks for multiple 3D design options.

Our in-house designers will work on your bespoke bottle design and its unique matching closure/cork.

If you are feeling inspired, send us images of what you have in mind.

We’ll then give you a price estimate for the mass production of your bottle.

Our designers can also work on gift boxes, sales/shipping cartons that match your branding.

If it’s a label you need, we can take care of that too. Paper or silk screen…the sky is the limit.

Mold & Proofing

Super Flint: USD 2200

Flint: USD 1200

NNPB: USD 7500-9000

Once the design is finalized, our skilled craftsmen begin the mold production process.

A one-time fee is charged, and all future maintenance and replacement costs will be fully covered by SGSBOTTLE.

Mold production typically takes around 10–15 days. Once completed, the mold will be sent to the manufacturing workshop for sampling, which usually takes an additional 7–10 days.

We’ll send 3–5 samples via express delivery for the client’s final approval.

MOQ

Super Flint: 12000pcs

Flint: 30000-50000pcs

NNPB: 1 million

Super Flint 420g or less: 30,000pcs

Super Flint above 420g: 120,00pcs

Flint: less than 180g: 50000pcs

Flint: above 200g: 30000pcs

NNPB: 1 Million

For large volume orders, the unit price per bottle is lower. Automated inspection machines can be used to improve the pass rate and reduce costs.

We will refund the mold cost after completing the production of 2 to 5 million bottles within one year.

Transportation & Time

USD $500 – $ 4000

Shipping of 40’HQ container from China to any destination worldwide.

It is recommended to fill a container in order to save on repeat transportation costs. We will always tell you how many bottles fit in 1 container before you place your order.

Depending on the bottle shape and packaging method, a 40HC container can typically hold approximately 26,000 to 32,000 bottles of 700-750ml each.

A container can hold approximately 70,000pcs to 90,000pcs bottles of 300-330ml each.

1

Understand your custom glass bottle design

With over 20 years of experience in design and customization, we focus on helping our clients turn ideas into reality more efficiently. Whether you provide a sketch, technical drawing, or 3D model, we quickly and accurately understand your vision, offer professional suggestions to optimize your design, reduce unnecessary costs, and streamline communication—saving you time and helping you bring products to market faster.

2

Custom Glass Bottle Drawing

We will quickly and accurately interpret your design intent through technical drawings and 3D models, providing clear data and detailed visualizations to help you confirm the design with confidence—saving time and minimizing back-and-forth revisions.

3

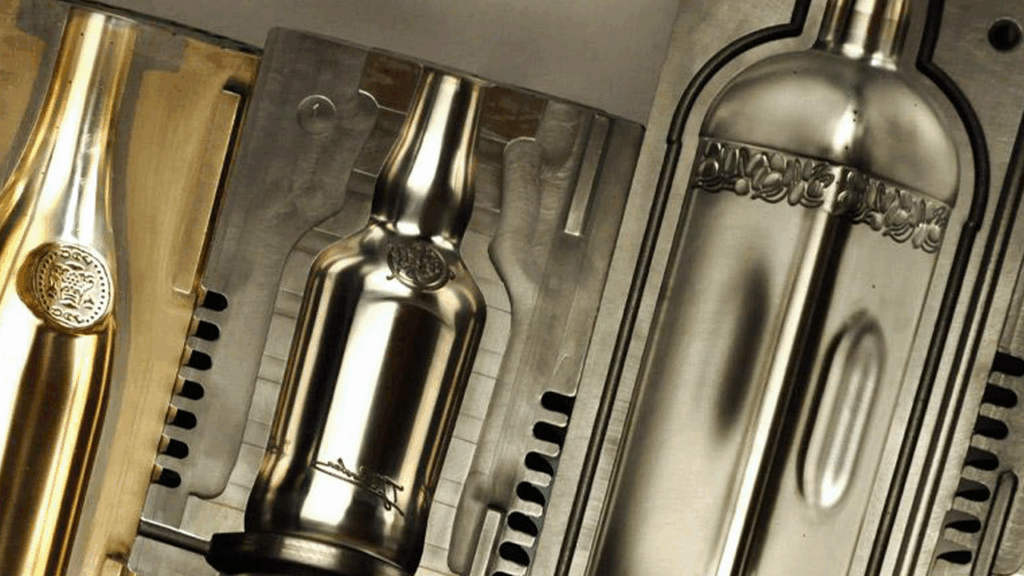

Making Custom Glass Molds

Molds are essential for bringing your glass packaging ideas to life. At Maidao Glass, we provide complete sets of production molds, typically suitable for around 500k – 1 Million units depending on the size and complexity. If a mold reaches the end of its lifespan—either during or after production—we will replace it free of charge, ensuring your production runs smoothly without extra cost.

4

Glass Bottle Samples Setup

Setting up samples before mass production is the most effective way to test your design. During this process, you will receive 3-5 physical samples for filling tests, lid compatibility checks, and commercial packaging trials. This not only gives you a real sense of the final product, but also provides the most efficient and low-cost opportunity to make design adjustments if needed.

5

Custom Glass Bottle Manufacturing and Packaging

To help you bring products to market efficiently and with confidence, we complete bulk production orders within 30–45 days. Each bottle goes through both automated and manual inspections tailored to your product’s requirements, ensuring consistent quality and reducing the risk of defects. We also provide a full range of decoration services—such as screen printing, spray coating, decals, and hot stamping—to support your branding needs and help your product stand out on the shelf.